Description

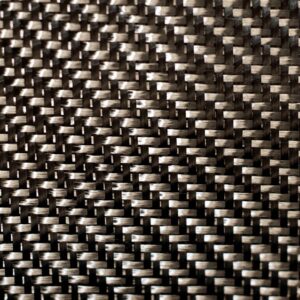

ACP’s Carbon Fiber Uni Roll Wrapped Tubing is manufactured by wrapping carbon fiber unidirectional prepreg tape onto a mandrel in multiple layers and orientations and cured at high temperatures and pressure.

The unidirectional layers are oriented in a 0/90 degree orientation with the majority of the fibers positioned in the longitudinal access. Fibers oriented at 90 degrees (hoop) are wrapped around the circumference to provide high crushing strength and stiffness. The fibers that run along the length, in the 0 degree direction, provide high bending strength and stiffness. This type of construction offers a high stiffness to weight ratio tube with increased bending stiffness and axial strength, a high crush resistance and tight inner diameter (ID) tolerances.

All of our roll wrapped tubes feature a slight rib texture spiraling along their length where shrink-tape has been used in the manufacturing process. If need be, this can easily be sanded and polished away.

Uses Include

- Aerospace Spars & Beams

- UAV Housing Components

- Frames & Supports

- Structural Components

- Interior Design

- Automation Equipment

- Recreational Equipment

Technical

Physical Properties

- Outer Diameter (OD): +/-.015″

- Inner Diameter (ID): +/-.010″

- Wall Thickness (WT): OD-ID/2

- Shape/Profile: Round

- Color: Natural dark gray to black

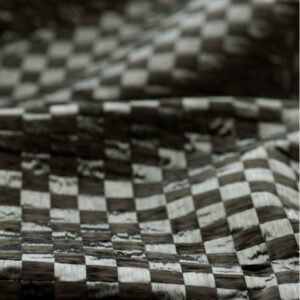

- Layup*: 0°/90° unidirectional orientation

- Process: Roll Wrapped

- Material: Unidirectional Carbon Fiber Carbon Fiber

- Resin Type: Epoxy with built in UV inhibitor

- Fiber Type: 33 to 35 MSI standard modulus carbon fiber Fiber

- Volume: 58%

- Finish: Gloss with slight spiral rib texture

- Thermal Properties: 150°F maximum

Technical Properties

- Tensile Strength: 275 ksi

- Tensile Modulus: 17 msi

- Compressive Strength: 132 ksi

- Compressive Modulus: 14.5 msi

- Torsional Strength: 15 msi

- Torsional Modulus: 1.3 msi

- Fatigue Strength: 90 (106)

- CTE: (-0.24 in/in/°F)(106)

- Glass Transition Temp: 100°C

- Density: 1.52 g/cm3

Please note: All data to be used as a guide only; not a specification. *We can create custom layup options to meet your design requirement.

Documents

Resources

Tips

Tips on how to use this product in certain applications are coming soon. If you would like to learn more about this product, give us a call at (800) 811-2009.

How to Guides

Customize

Need something different? We’ve got you covered.

As a leading manufacturer of composite structures you can rely on us to provide rapid, cost-effective and high-quality solutions to meet and exceed your project requirements.

We MAKE it.

Our design and manufacturing team can work with you to fabricate custom rods.

- Fiber Selection

- Manufacturing Process

- Layup/Construction

- Surface Finish

- Outer Diameters from .250″ to 3.00″*

- Lengths up to 8’*

- Finishing

*Available size options are contingent on tooling and material availability. Minimum order quantities may apply.

We CUSTOMIZE it.

- CNC Machining

- Cutting

- Slotting

- Drilling

- Grinding

Request a Quote

Contact us today to discuss your requirements. Already know what your looking for?

REQUEST A QUOTE TODAY!

Stock Cutting

ACP can cut stock rods and tubes to custom sizes in-house to hold tight tolerances for convenience and availability.

- +/- 0.25″ Tolerance $10.00 setup fee per cut length $1.00 per cut

- +/- 0.125″ Tolerance $50.00 setup fee per cut length $1.00 per cut

- Higher Tolerance Call 1-800-811-2009 for quote

FAQ's

FAQ’s

Q: How is the wall thickness calculated?

A: Subtract the inner diamter (ID) from the outer diamer (OD) and divide that number by 2. Example: 1.624″OD-1.50″OD= .124″. .124″/2=.062″ Wall thickness (WT)

Reviews

There are no reviews yet.