Description

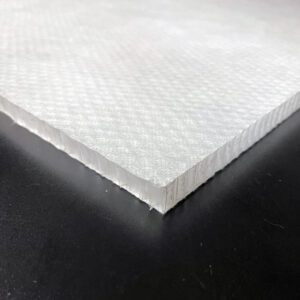

Polyurethane Foam Core is a CFC-free, rigid, closed-cell, flame-retardant foam core and has a density of 6 pounds per cubic foot (PCF). It exhibits a high strength-to-weight ratio due to its cellular structure and cross-linked resin. Because of its closed-cell structure, Polyurethane Foam Core has great resistance to water absorption, and will not swell, crack, or split on exposure to water.

Features/Benefits

- Stable and inert

- Flame retardant

- High strength-to-weight ratio from cross-linked resin

- Resistant to most chemicals and solvents

- Easily shaped with common woodworking tools

- Performs well as wood replacement

- Will not support fungal growth

Uses Include

- Models and design prototypes

- Composite core, especially where flame retardation is important

- Radioactive materials (RAM) transportation packages

- Vacuum form dies and mold patterns

- Load bearing

- Dielectric material for radomes and antennas

Technical

Physical Properties

- Core Thickness: +/- .030″

- Density: 6 PCF

Structural Foam Properties

- Compressive Strength ǁ to rise: 154 psi @ 75°F

- Compressive Strength⊥ to rise: 139 psi @ 75°F

- Compressive Modulus ǁ to rise: 4275 psi @ 75°F

- Compressive Modulus⊥ to rise: 3437 psi @ 75°F

- Tensile Strength ǁ to rise: 182 psi

- Tensile Strength⊥ to rise: 174 psi

- Tensile Modulus ǁ to rise: 5949 psi

- Tensile Modulus⊥ to rise: 5662 psi

- Shear Strength ǁ to rise: 116 psi

- Shear Strength⊥ to rise: 116 psi

- Shear Modulus ǁ to rise: 4133 psi

- Shear Modulus⊥ to rise: 1457 psi

- Flexural Strength ǁ to rise: 226 psi

- Flexural Strength⊥ to rise: 210 psi

- Flexural Modulus ǁ to rise: 5944 psi

- Flexural Modulus⊥ to rise: 5421 psi

- CTE: ~3.4 x 105/in/in/°F

- Closed Cell Content: 95.6%

- Hardness, Shore-D: 11.1

- Water Absorption: 0.17 lbs/ft²

- Specific Heat @ 25°C: 0.353 BTU/lb-°F

- Heat Combustion: 11706 BTU/lb

- Thermal Conductivity: 0.205 BTU*in/ft²*°F*h

- Max Temp: 260°F

Please note: All data to be used as a guide only; not a specification. The technical information is for the stand alone raw materials, not the constructed panel.

Documents

Requirements

Resources

Resources

Tips

When using as a tooling board, it is recommended that you do a rough cut first, leaving 1-3 mm of material for finishing. Use caution at edges and tight corners to avoid chipping at the start of a new pathway and when exiting the foam.

Resources

Customize

Customize

Need something different? We’ve got you covered. As a leading manufacturer of composite structures you can rely on us to provide rapid, cost-effective and high-quality solutions to meet and exceed your project requirements. We SOURCE it. When a stock material doesn’t meet your requirements, we can utilize our supplier relationships to acquire materials that best fit your needs.

- Density

- Grade

- Thickness

- Sizes up to 48″ x 96″

We CUSTOMIZE it. We can tailor our stock products to meet your needs by offering the following services:

- CNC Machining

- Cutting

- Contouring/Profiling

- Potting

- Sandwich Panel Construction

Shipping

Due to packing requirements to preserve material integrity, the Polyurethane Foam requires custom packaging. Additional handling fees apply for all foam orders. The below fees will be automatically added to the order.

- $30.00 for 24” x 48”

- $50.00 for 48” x 48”

- $85.00 for 48” x 96” – LTL Freight Only

Final shipping charges may not be available at the time of ordering. A quote can be requested or shipping charges can be automatically billed at the time of shipment.

Reviews

There are no reviews yet.