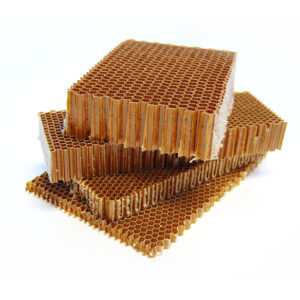

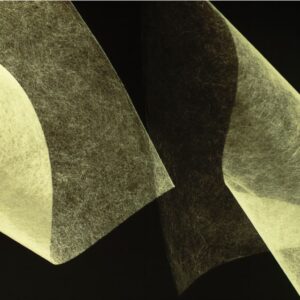

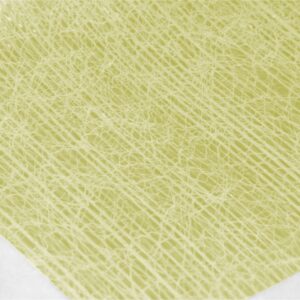

Kevlar® fibers were first developed by DuPont® in the early 1970’s. These fibers are an organic fiber found in the aromatic polyamide (aramid) family and are typically gold in color. Aramid (Kevlar®) is best suited for applications where toughness is preferred. In addition, Aramid (Kevlar®) fibers offer high strength, low weight, desired stiffness and thermal stability. These fibers are 43% lighter than fiberglass, twice as strong as E-glass, and ten times as strong as aluminum. These unique properties make it an exceptional fiber for use in composite reinforcements, ballistics applications, ropes, cables and protective apparel. Due to these unique properties we recommend using specialized shears for cutting. Aramid (Kevlar®) fiber is difficult to sand and is adversely affected by UV light, so it is often buried under fiberglass or other material. Properties of Kevlar® High Tensile Strength at Low Weight Low Elongation to Break High Modulus (structural Rigidity) Low Electrical Conductivity High Chemical Resistance Low Thermal Shrinkage High Toughness (Work-To-Break) Excellent Dimensional Stability High Cut Resistance Flame and Heat Resistance, Self-Extinguishing KEVLAR® is a registered trademark of E.I. du Pont de Nemours and Company and is used with permission

Showing all 8 results

By selecting pre-approve as the shipping option you agree to be billed separately for the actual cost of shipping after the order ships.