Creating a Pleat When Vacuum Bagging

Vacuum Bag pleating is a common practice used when laying up a part that has a deep mold or complex contours. Pleats allow the vacuum bagging film to form evenly around the part, creating consistent vacuum pressure.

When laying down bagging film on your laminate it is important to take into consideration the size of the bag film and the shape of you part. If your part has a deep mold or complex shape understanding how the bag will behave when vacuum is pulled will help to achieve bagging success.

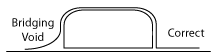

If you bag is too small or tight it will cause bridging at corners and elevations. If bridging occurs there will be no pressure applied to that area and could cause a tear in the bag.

Bridging is when the bag does not fold down completely on an edge leaving a rounded void.

With the use of tucks and pleats you can use a larger bag and reduce bridging. Learn how to create a pleat below.

WHAT IS A PLEAT?

A pleat is a fold made by doubling the vacuum bag upon itself and pressing it together with sealant tape to form a tight seal.

One faces certain challenges when creating pleats: wrinkles, leak sites, and a time consuming learning curve.Creating pleats prior to attaching your vacuum bagging film is an easy way to prevent leaks, wrinkles and make the lay-up of the vacuuming bagging film a simpler step.

Before pleating the vacuum bagging film, attach the sealant tape to the flange. Any excess resin needs to be have been cleaned with acetone prior to the placement of the sealant tape. Apply the sealant tape around the entire flange; making sure to press down firmly to create a good bond. Leave the protective paper on the sealant tape.

A flange is a flat area of a mold that extends perpendicularly from the edge of the molding surface

After attaching the sealant tape, decide the size and location of the pleat(s). Pleats should be placed where the vacuuming bagging film would normally bunch up, on the down side of a contoured edge. The size of the pleat is determined by the height of the mold. Usually it is best to have your pleat be at least half the height of the mold.

Now it is time to cut the vacuum bagging film to fit the mold. Make sure that there is enough material to allow for the pleats, to avoid stretching of the bagging film and to prevent bridging areas when the vacuum is applied. When cutting the bagging film to size, make sure the film is at least 30% larger than the sealant tape perimeter or greater if it is a deep mold.

CREATING THE PLEAT

After the sealant tape has been adhered to the flange, the vacuuming bagging material has been cut and the size and location of the pleat has been decided, it is time to create the pleat.

- Cut a separate piece of sealant tape that is 2x the height of your pleat, plus extra on each end. The extra sealant tape will be used to adhere the cut strip to the sealant tape on the flange. The height of the pleat should measure at least half the height of the mold. Leave the protective paper on.

- Lay the cut piece of sealant tape, protective paper side down, in the determined location. (Figure A.)

- Take the cut vacuum bagging film and lay it on top of the cut piece of sealant tape. Press firmly to create a solid bond. Make sure no creases or wrinkles have formed.

- Once the vacuum bagging film has been adhered to the cut piece of sealant tape, remove the protective paper.

- Take your finger and place it on the underside and in the center of the cut piece of sealant tape. This will become the top of the pleat. (Figure B.)

- Using your free hand, pinch the sealant tape over your finger, creating a small point. Make sure they create a solid seal.

- Now, begin pressing the two ends of the cut piece of tape together. Firmly press to create a strong bond. (Figure C.)

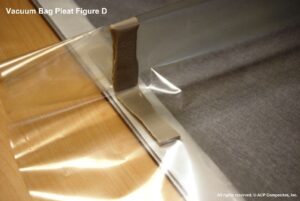

- Once the pleat is the desired height, as previously determined, stop pressing the two ends together. Press firmly to create a bond. Once completed, the tape will stand tall. The excess tape on either side will be used to adhere the cut piece to the sealant tape already attached to the flange. (Figure D.)

- After all pleats are created, it is time to attach the vacuum bagging film to the sealant tape on the flange. Drape the bagging film over the entire part.

- Starting at a corner of the mold, peel the protective paper from the sealant tape. Press the edge of the bag onto the sealant tape while pulling the bag taut enough to avoid wrinkles. At first, press with light pressure until the whole part is enclosed to insure no wrinkles have formed. If a wrinkle has formed, peel back the vacuum bagging film, pull taut and replace.

- To attach the pleat, pull the protective paper just past the pleat. Press one side of the pleat to the sealant tape of the flange.(Figure E.) Make sure the two pieces line up and that they are firmly pressed together.

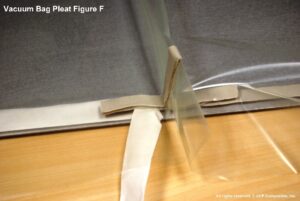

- Do the same on the opposite side of the pleat. (Figure F.)

- Once the whole part is enclosed, make sure no wrinkles have been formed. Press firmly along the sealant tape to complete the seal.

- A pleat has been formed, and vacuum is ready to be applied. (Figure G.)