Description

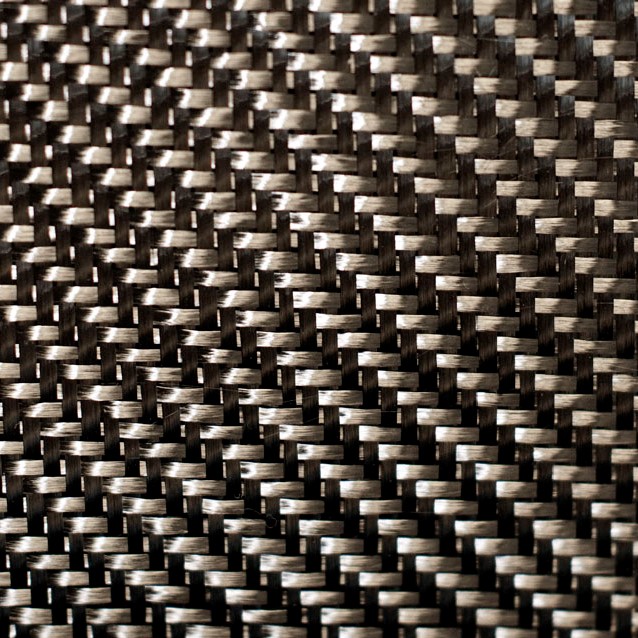

Our Carbon Fiber Room Temperature Storage (RTS) Prepreg is a 5.8oz/yd2 (198gsm) 2×2 twill weave fabric woven from 3K carbon fibers and impregnated with a thermosetting epoxy resin system. It can be stored at room temperatures and does not require freezer storage. With the long out life of the resin matrix, the carbon fiber prepreg can be shipped and processed at room temperatures. It is ideal for use when a long shelf life is desired, high-temperature capabilities are not required and controlled resin content is wanted.

The 2×2 twill construction provides the classic “carbon fiber” appearance so desirable on composite parts and makes it a highly pliable fabric is ideal for applications with compound curves. The unique epoxy resin system allows for various flexible cure cycles and has a long out-life.

Please allow extra order processing time when order prepreg fabrics.

Technical

Documents

Physical Properties

- Style: 284

- Weave: 2×2 Twill Weave

- Weight: 5.8 oz/yd² (198 gsm)

- Thickness: .0087″

- Width: 50″

- Fabric Count (Warp x Fill): 4.95 x 4.95 +/-

- Fiber Type: 3K T300 Carbon Fiber Standard Modulus PAN, 33MSI

- Resin Matrix: Epoxy Resin Content: 39% +/-3% by Weight

Technical Resin Properties*

- Density: 1.22 g/cc

- Tensile Strength: 76.5 MPa / 11.1 kpsi

- Tensile Modulus: 10.7 GPa / 427 kpsi

- Strain (% Elongation) : 3.75%

DMA – Dry Glass Transition

- Glass Transition – E” Peak: 132°C / 270°F

- Glass Transition – E’ Onset: 130°C / 265°F

- Glass Transition – Tan δ Peak: 146°C / 295°F

DMA – Wet Glass Transition**

- Glass Transition – E” Peak: 86°C / 187°F

- Glass Transition – E’ Onset: 81°C / 179°F

- Glass Transition – Tan δ Peak: 98°C / 208°F

- Water Abbsorbtion**: 3.8%

Composite Properties***

- 0° Tensile Strength: 0.75 GPa / 110 kpsi

- 0° Tensile Modulus: 76 GPa / 11 Mpsi

- 0° Tensile Percent Strain: 1.0 %

- 0° Tensile Poisson’s Ratio: 0.20

- 0° Compressive Strength: 0.62 GPa / 9.0 x 101 kpsi

- 0° Compression Modulus: 52 GPa / 7.5 Mpsi

- Short Beam Strength: 63 MPa / 9.1 kpsi

- Flexural Strength: 0.74 GPa / 108 kpsi

Cure Cycles

Option 1

- ≤ 5°F-per-minute ramp up to 310°F (154°C), hold for 1 hour.

- < 5°F-per-minute ramp down to at least 150°F (66°C) before removing from oven.

Option 2

- ≤ 5°F-per-minute ramp up to 290°F (143°C), hold for 2 hours.

- < 5°F-per-minute ramp down to at least 150°F (66°C) before removing from oven.

Option 3

- ≤ 5°F-per-minute ramp up to 270°F (132°C), hold for 4 hours.

- < 5°F-per-minute ramp down to at least 150°F (66°C) before removing from oven.

Shelf Life/Storage

Material should remain sealed when not is use and stored indoors, out of the weather.

- 6 months from date of manufacture when the maximum temperature storage does not exceed 90°F(32°C)

- 12 months from date of manufacture when the maximum temperature storage does not exceed 75°F(24°C)

- 30 months from date of manufacture when the maximum temperature storage does not exceed 0°F(-18°C), with an additonal 6 months at <75°F (24°C).

Please note: All data to be used as a guide only; not a specification. *Cure cycle: 1 hour at 154°C **DMA wet glass transition and water absorption measured after 24-hour water boil ***Reinforcement: T300-3K 2×2 twill 50” carbon fiber fabric. Composite properties are express to two significant figures. Cure cycle: 4 hours at 132°C (270°F), via vacuum bag oven cure, tests conducted at 22°C (72°F)

Reviews

There are no reviews yet.