Description

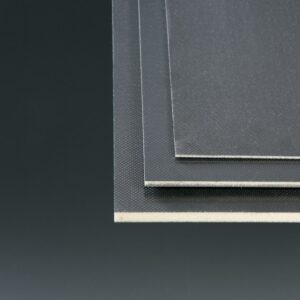

ACP’s Fiberglass Fiber Foam Sandwich Panels are ideal panels for a wide range of applications requiring flat, lightweight and rigid specifications. They are manufactured by ‘sandwiching’ a 6 PCF polyurethane foam from LAST-A-FOAM between layers of self-adhesive fiberglass prepreg. Our sandwich panels are cured with high temperature and under pressure resulting in fully consolidated fiberglass skins that are completely bonded to the foam core. By separating the fiberglass skin with an foam core, these sandwich panels offer greater strength properties than those of the skins alone.

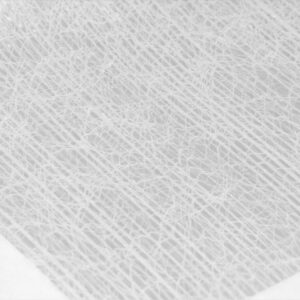

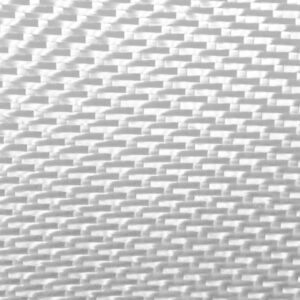

Using fiberglass prepreg for the outer layers creates structural skins that offer high strength, moderate tensile strength and compressive strength, dimensional stability, design flexibility and excellent electrical resistivity.

Manufactured with a with lightweight, high density structural foam, our foam core sandwich panels demonstrate the light weight, high strength and stiffness properties desired in a foam core panel and are lighter than balsa core panels. By using a structural foam, these panels feature higher compressive strength and crushing resistance than panels manufactured with a non-structural foam core. The LAST-A-FOAM® is a flame-retardant polyurethane (PU) foam and has great resistance to water absorption, and will not swell, crack, or split on exposure to water. This series is non-abrasive and can be machined with standard high-speed steel (HSS) cutting tools. They remain a more economical option and are ideal for applications that require low water absorption and good sound and thermal insulation.

Uses Include

- General Purpose Aviation Panels

- Composite Core

- Aircraft Interiors

- Interior Design

- Marine Paneling

Technical

Physical Properties

- Core Thickness: .125″, .250″, .500″

- Ply Thickness: .008″

- Total Thickness (TPT) Tolerance: +/- 15%

- Length/Width Tolerance: +/- 0.50″

- Core Material: 6 PCF Polyurethane Foam

- Skin Material: 7781 Fiberglass Prepreg

- Resin Content: 42% +/- 3%

Prepreg Average Properties

- Glass Transition Temperature: 209°F

- Cured Ply Thickness1 @ 75°F: .010″

- Climbing Drum Peel2 @ 75°F: 9 in.lb/in.

- Flatwise Tensile Strength @ 75°F: 1400 psi

- Tensile Strength @ 75°F: 65 ksi

- Tensile Modulus @ 75°F: 3.7 msi

- Compressive Strength @ 75°F: 65 ksi

- Compressive Modulus @ 75°F: 3.6 msi

- Flexural Strength @ 75°F: 89 ksi

- Flexural Modulus @ 75°F: 3.5 msi

- Interlaminar Shear Strength @ 75°F: 6.9 ksi

Please note: All data to be used as a guide only; not a specification.1Tested on a 12 ply laminate, cured at 1hr at 250°F. 22 ply skins on 3.0 PCF, 1/8″ cell, 1/2″ nomex honeycomb cured 1 hr at 250°F under 40psi.

Structural Foam Properties

- Density: 6.0 PCF

- Compressive Strength ǁ to rise: 154 psi @ 75°F

- Compressive Strength⊥ to rise: 139 psi @ 75°F

- Compressive Modulus ǁ to rise: 4275 psi @ 75°F

- Compressive Modulus⊥ to rise: 3437 psi @ 75°F

- Tensile Strength ǁ to rise: 182 psi

- Tensile Strength⊥ to rise: 174 psi

- Tensile Modulus ǁ to rise: 5949 psi

- Tensile Modulus⊥ to rise: 5662 psi

- Shear Strength ǁ to rise: 116 psi

- Shear Strength⊥ to rise: 116 psi

- Shear Modulus ǁ to rise: 4133 psi

- Shear Modulus⊥ to rise: 1457 psi

- Flexural Strength ǁ to rise: 226 psi

- Flexural Strength⊥ to rise: 210 psi

- Flexural Modulus ǁ to rise: 5944 psi

- Flexural Modulus⊥ to rise: 5421 psi

- CTE: ~3.4 x 105/in/in/°F

- Closed Cell Content: 95.6%

- Hardness, Shore-D: 11.1

- Water Absorption: 0.17 lbs/ft²

- Specific Heat @ 25°C: 0.353 BTU/lb-°F

- Heat Combustion: 11706 BTU/lb

- Thermal Conductivity: 0.205 BTU*in/ft²*°F*h

Please note: All data to be used as a guide only; not a specification. The technical information is for the stand alone raw materials, not the constructed panel.

Documents

~Weight per ft²

- .125″ 1 Ply: 3.5 oz.

- .250″ 1 Ply: 4.6 oz.

- .500″ 1 Ply: 6.6oz.

- .125″ 2 Ply: 6 oz.

- .250″ 2 Ply: 6.9 oz.

- .500″ 2 Ply: 8.9 oz.

Customize

Need something different? We’ve got you covered.

As a leading manufacturer of composite structures you can rely on us to provide rapid, cost-effective and high-quality solutions to meet and exceed your project requirements.

We MAKE it.

Our design and manufacturing team can work with you to fabricate custom rods.

- Fiber Selection: Carbon Fiber, Fiberglass, Kevlar®, Other

- Skin Thickness

- Core Selection: Honeycomb (aluminum, plastic, Nomex) and Foam (polyurethane, PVC, ABS & others)

- Core Thickness

- Layup/Construction

- Surface Finish

- Sizes up to 60″ x 120″*

*ACP has a maximum work envelope of 60″ x 120″. Available options are contingent on tooling and material availability. KEVLAR® is a registered trademark of E.I. du Pont de Nemours and Company and is used with permission.

We CUSTOMIZE it.

- CNC Machining

- Cutting

- Edge Closeouts

- Rebate Edges

- Hard Fix Points

- Fixtures

- Counter Boring

- Bonding

- Joining

- Assembly

Request a Quote

Contact us today to discuss your requirements. Already know what your looking for?

REQUEST A QUOTE TODAY!

Reviews

There are no reviews yet.