Description

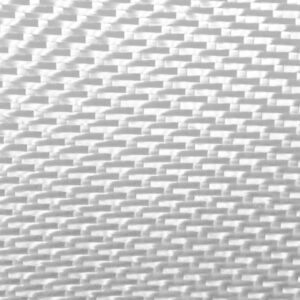

Braided Sleeving is a biaxial braid of precisely oriented fibers of maximum stiffness, torsial stability and compressive strength. Woven with an aramid fiber in a 45° orientation, these Braided Aramid Sleeves have the unique ability to easily and repeatably conform to various shapes while delivering the impact and abrasion resistance of Kevlar® fibers.

The braided fiber orientation allows the sleeve to expand by 20-25% of their base diameter and to be pulled down by 60-65% of their base diameter. As the sleeving is pulled over a product or mandrel, the braid takes on the exact shape and dimension of the part. This behavior makes Braided Sleeves predictable and lend themselves to easy and precise manufacture of composite parts.

Price breaks after 100 pounds – available upon request.

- Tubing

- Prosthetic’s

- Hockey Sticks

- Insulators

- Abrasion and cut resistant

- Heat resistant

- Braided orientation allows for 20-25% increase in diameter