Unmanned systems

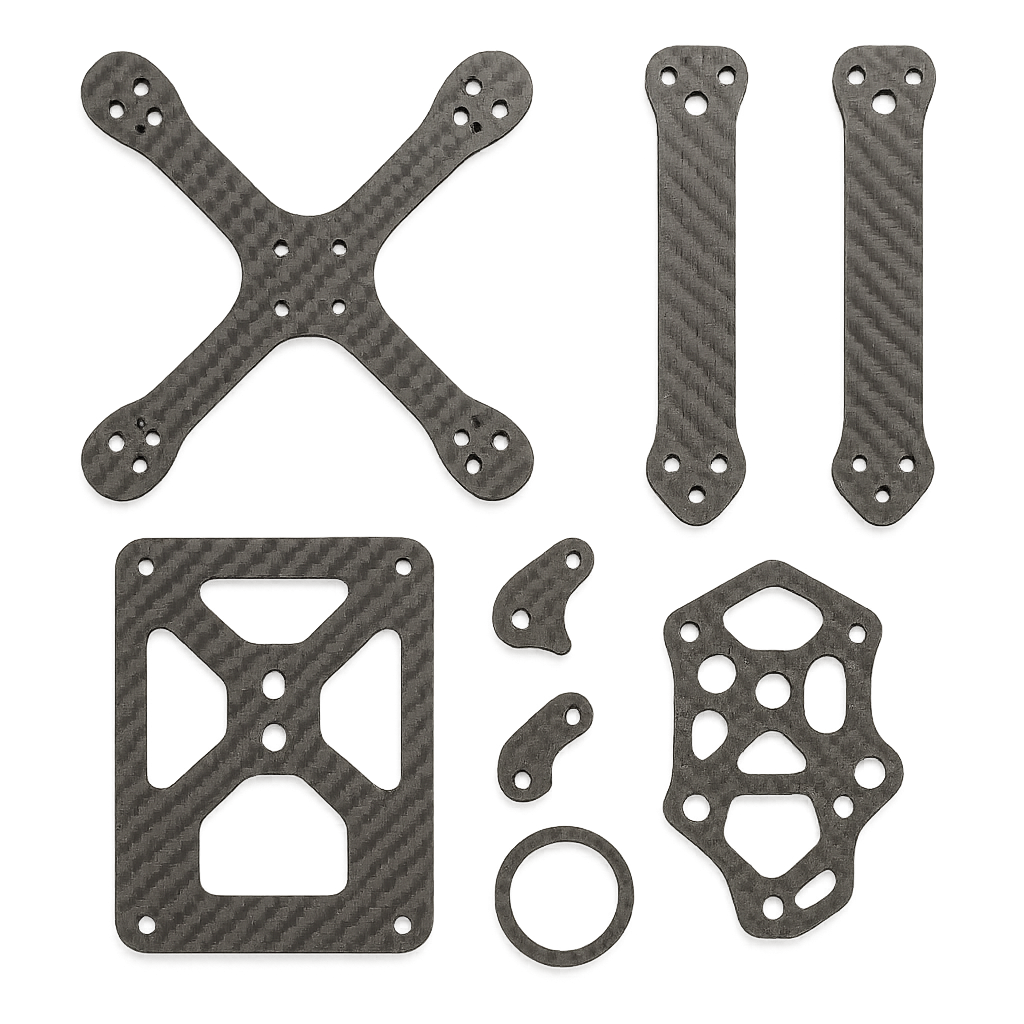

Advanced Composites for UAS, UAV & Drones

Trusted by

WHEN MISSION-CRITICAL MATTERS

ACP Composites transforms unmanned systems with high-strength, light-weight composite solutions that deliver. Backed by 40 years of composites experience, we turn complex designs into durable structures that extend range, enhance payload capacity, and elevate mission success. From tactical UAVs to long-endurance platforms, military and commercial teams trust ACP when reliability matters most.

Fuselages, Empennages, & Nosecones

ACP Composites expertly crafts fuselages, empennages, and nosecones to your exact specifications and weight targets. With seamless integrations and proven manufacturing processes, we help your UAV fly lighter, smarter, faster, and farther.

Wings & Stabilizers

Take your UAV to new heights with wings and stabilizers engineered for optimal lift, strength, and efficiency. ACP Composites delivers ultralight, rigid airfoils with accurate control surfaces and versatile payload mounts manufactured to spec and backed by our quality assurance.

Optical Domes & Enclosures

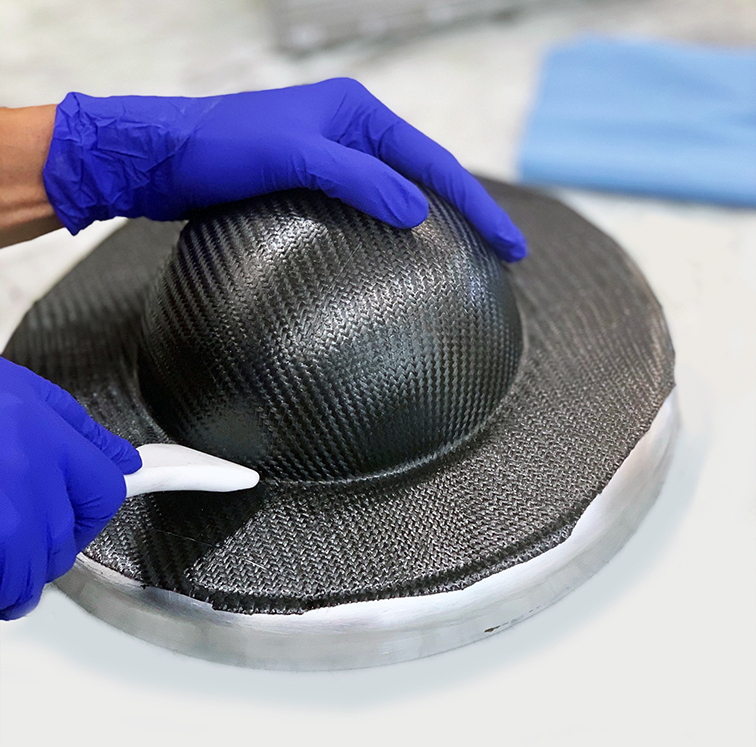

Unlock peak sensor performance with crystal-clear optical domes and durable enclosures designed for multi-wavelength visibility. ACP’s manufacturing services provide additional environmental protection and interference shielding, giving your sensors the clearest possible view.

Hatches, Covers & Fairings

Streamline your UAV with custom hatches, covers, and fairings built for aerodynamic efficiency. ACP builds your precision-fit components, scalable from prototype to production, with reliable seals and smart thermal design to reduce drag and boost range.

Assemblies & Integrations

ACP Composites seamlessly integrates control systems, communications, sensors, and payloads with high-strength structures producing flight-ready components. With bonded inserts and fully assembled airframes, we simplify your build and accelerate deployment.

Carbon Fiber & Fiberglass

- Unidirectional Prepregs

- Twill & Plain Weave Prepregs

- Thermosets & Thermoplastics

Bonded Aluminum Structures

- Battery Casings and Housings

- Chassis and Structural

- Airframes Components

Hybrids & Exotics

- Carbon/Kevlar®

- Carbon/S-Glass

- Specialty

Need to discuss your materials requirements?

UAS Manufacturing Capabilities

ACP Composites solves complex design challenges with advanced molding techniques, expert lay-ups, and deep DFM expertise. Every component is built to spec with rigorous quality controls, accelerating time to market and scaling smoothly from prototype to production.

Thermoset Prepreg layup

ACP’s specialized lay-up processes give you precise fiber orientation and control to optimize strength, stiffness, and performance to meet the demands of your UAV design. Access a wide selection of uni- and woven-fiber prepregs and resin systems tailored to your specifications.

Bladder & Compression Molding

From lightweight fuselage sections to solid engine mounts, ACP Composites offers bladder and compression molding to produce high-performance components for complex UAV geometries, all supported by our advanced in-house tooling capabilities.

foam core structures

Foam core structures from ACP Composites reduce overall platform weight without sacrificing durability, ideal for extending flight time and increasing payload. Our impact-resistant cores mold easily into complex shapes with exceptional strength-to-weight ratio.

design-for-manufacture

With over 40 years of composite expertise, ACP Composites brings unmatched DFM support to every UAS project. We help reduce complexity, cost, and lead time—ensuring your components are optimized for efficient, scalable production from the start.

trusted across UAS industries

Whether you’re building surveillance, heavy-lift, or mapping platforms, ACP Composites brings the advanced composites you need to perform. From Military & Defense to agriculture and construction, we support every sector of UAS manufacturing with materials and expertise that make your systems lighter, stronger, and more efficient.

- Military & Defense

- Logistics

- Agricultural

- Public Safety

- Construction

- Environmental

- Surveying & Mapping

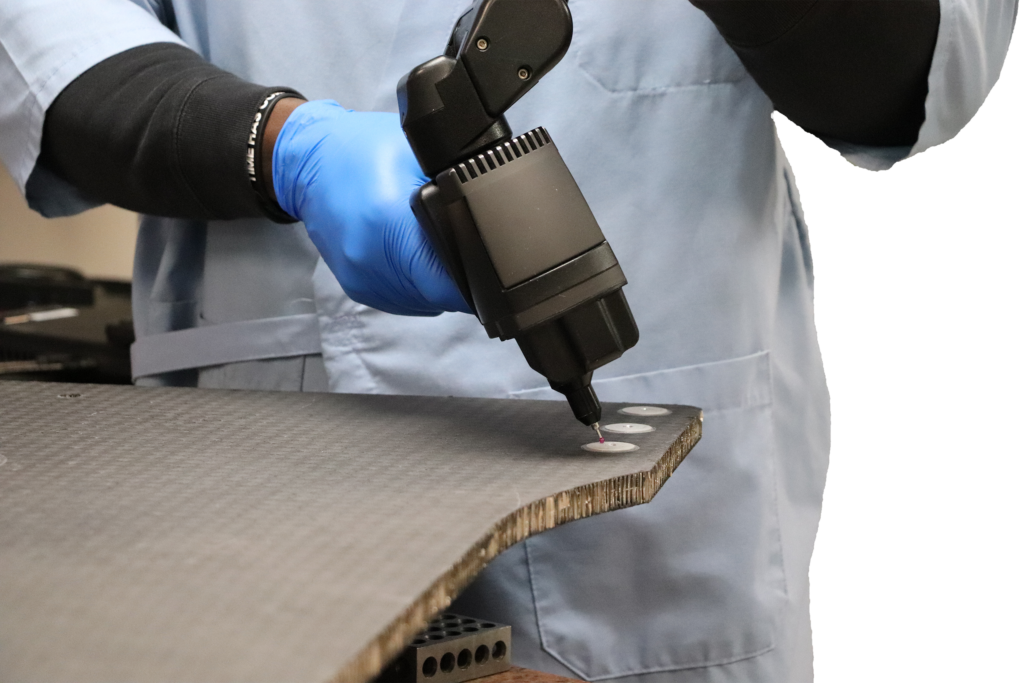

Quality is our Design

At ACP Composites, quality and innovation drive every UAV component we produce. Our high-tolerance flight parts and mission-critical assemblies push the limits of composite manufacturing to meet the evolving demands of unmanned systems and exceed industry standards.

- Full Material & Process Traceability

- FAIR

- In-Process Inspection

- Multi-Dimensional Testing

- Romer Arm Inspection

- NIST Certified Calibration

Partner with ACP Composites and experience the difference that our unwavering commitment to quality and innovation can make for your project.

Lighter. Stronger. Flight-Ready.

ACP Composites turns your UAV designs into high-performance, flight-ready components, built right, every time. From bladder and compression molding to thermoset prepreg layup and foam core structures, we deliver the lightweight strength UAV platforms demand. Whether you’re prototyping or scaling to production, our Design-for-Manufacture (DFM) expertise helps you move faster and smarter.

We add serious value with services like precision kitting, multi-axis CNC machining, bonded inserts, and full assemblies so you get complete, integration-ready parts. Backed by AS9100:D and ISO 9001:2015 certifications, our quality is proven with rigorous processes and inspections using a suite of advanced testing equipment.

Ready to launch smarter, lighter, and faster? Let’s build what’s next together.

Stronger Materials. Smarter Designs.

ACP Composites solves complex design challenges with advanced molding, expert lay-ups, and deep DFM expertise. Every part is built to spec with rigorous quality controls—accelerating delivery and scaling seamlessly from prototype to production.

Strength

Get performance at a fraction of the weight without compromising structural integrity. ACP Composites uses the highest quality composite materials to produce parts that improve flight time, fuel efficiency and payload capacity.

Durability

ACP’s composite expertise means structures that outperform traditional materials, resisting fatigue, corrosion, and impact. Your platform gains longer life, less maintenance, and reliable mission performance.

Resistance

From high altitudes to high heat, UAVs face extreme conditions. ACP’s components are built for reliable performance with a range of added services to enhance environmental durability and shielding protection.

Customization

Work with the ACP team to customize fiber orientations for added strength and stiffness exactly where it’s needed. The result? Improved control, maneuverability, and optimized flight performance for complex profiles.

Integration

ACP’s molded composite components merge multiple functions into one part, cutting assembly time and potential failures. Your design and supply chain gain efficiency and reliability.

Frequently Asked

Questions

Can’t find what you’re looking for?

Please reach out to our experts.

Carbon fiber-reinforced polymers (CFRPs) are the most commonly used composites in UAS due to their high strength-to-weight ratio, stiffness, and durability. Kevlar and fiberglass are also used in specific applications requiring impact resistance or electromagnetic transparency.

Composites used in UAVs are engineered to withstand harsh conditions such as UV exposure, high humidity, temperature swings, and corrosive environments. Proper resin and fiber selection ensures long-term reliability in field operations.

Composites are generally resistant to corrosion and fatigue, but exposure to UV, moisture, and extreme temperatures can degrade performance over time. Proper material selection and protective coatings are key.

We offer aerospace-grade Nomex®, Apex Carbon Fiber and aluminum honeycomb, PMI, PVC, and foam cores, each selected based on compressive strength, density, and thermal behavior. These are commonly used in radomes, control surfaces, and bulkheads to maximize stiffness with minimal weight.

Typical dimensional tolerances for composite UAV parts range from ±0.010″ to ±0.030″, depending on the part size, geometry, and tooling. For precision components, CNC post-machining and CMM inspection can achieve tighter tolerances down to ±0.005″.

Yes. We offer design-for-manufacturing (DFM) feedback to ensure your part can be produced efficiently and reliably. This may include guidance on ply orientation, tooling splits, draft angles, and allowable tolerances.

Yes. We routinely install metal or composite inserts for payload mounts, access points, and structural reinforcement. Bonded assemblies and multi-part integration are available as part of our in-house composite assembly services.

Yes. We support rapid prototyping through in-house tooling, composite layup, trimming, and assembly services. Our prototyping process allows you to test form, fit, and function before committing to full-scale production.

We offer a seamless transition from prototyping to low- and mid-rate production, including tooling optimization, repeatable layup documentation, and quality-controlled workflows. Our certified quality system ensures consistency across batches.

We are certified to AS9100D and ISO 9001:2015, ensuring compliance with rigorous aerospace industry standards. These certifications cover everything from material traceability to process control and final inspection.

We follow AS9100D and ISO 9001:2015 certified quality systems, using material traceability, process documentation, and inspection tools like the ROMER Arm to verify geometry and structural integrity throughout production.

To begin discussing your project, we typically need your CAD files (STEP or IGES). Laminate schedule, performance specifications, and any relevant tolerance, bonding, or assembly details can also be sent. Drawings and usage context also help optimize for manufacturability.