Holiday Closure

Our offices will be closed for Memorial Day Fri. May 24th-Mon. May 27th as we remember and honor our nation’s heroes.

We will be back in the office on Tues. May 28th.

Holiday Closure: Our offices will be closed Monday Dec 15th to Wednesday Dec 18th for Inventory.Additionally, we will be closed for the holiday season from Dec 24th thru Jan 2nd, returning to normal business on Jan 5th. We want to wish you a happy holiday season. Dismiss

Skip to contentCertified quality programs, dedicated inspection teams and a commitment to consistent results.

Extensive prototyping, engineering and tooling capabilities to fit any project.

Rapid, Cost-Effective And High-Quality Solutions That Exceed Industry Standards.

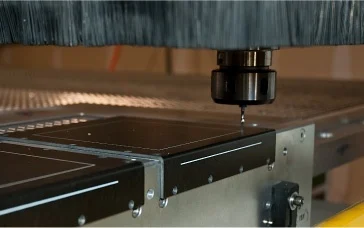

Explore our state-of-the-art facility housing the most advanced manufacturing equipment.

Discover the machining and cutting capabilities of our 5 Axis CNC and other machining equipment.

See how our exclusive composite products and in-stock materials provide the solutions you need.

Discover the technology, ideas, and people driving uncrewed systems and autonomy forward.

By selecting pre-approve as the shipping option you agree to be billed separately for the actual cost of shipping after the order ships.