Holiday Closure

Our offices will be closed for Memorial Day Fri. May 24th-Mon. May 27th as we remember and honor our nation’s heroes.

We will be back in the office on Tues. May 28th.

Certified quality programs, dedicated inspection teams and a commitment to consistent results.

Extensive prototyping, engineering and tooling capabilities to fit any project.

Rapid, Cost-Effective And High-Quality Solutions That Exceed Industry Standards.

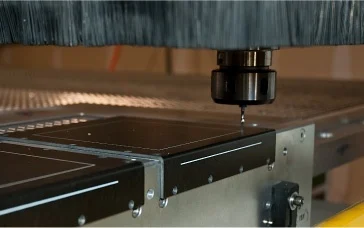

Explore our state-of-the-art facility housing the most advanced manufacturing equipment.

Discover the machining and cutting capabilities of our 5 Axis CNC and other machining equipment.

See how our exclusive composite products and in-stock materials provide the solutions you need.

Discover the technology, ideas, and people driving uncrewed systems and autonomy forward.

By selecting pre-approve as the shipping option you agree to be billed separately for the actual cost of shipping after the order ships.