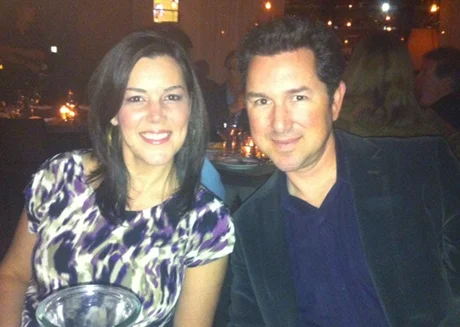

- Husband and wife team, George and Barbara Sparr, founds Aerospace Composite Products in Farmington, CT

- Sells first product

- Exhibits at first trade show

- Moves from Connecticut to California

- Moves into first manufacturing and distribution facility located in San Leandro, CA

- Moves into first manufacturing and distribution facility located in San Leandro, CA

- Launches first website

- Supplies carbon fiber tubes for softball bat reinforcement

- Becomes incorporated

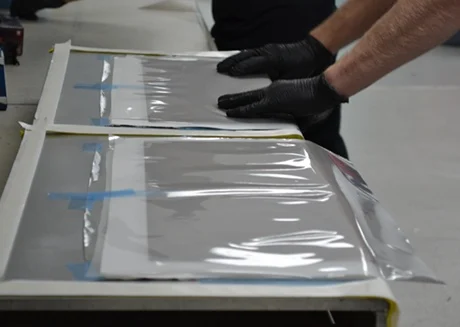

- Starts supplying radiolucent laminates to an industry leader in X-Ray Detectors

- Relocates from San Leandro to Livermore, doubling facility size

- Purchases first Autoclave

- Purchases first CNC Machine

- Interviewed by the MythBusters team for a composite based episode

- Son, Justin Sparr, joins the team

- Daughter, Jessica Sparr, joins the team

- Rebrands as ACP Composites, Inc.

- Moves into 33,000 square foot facility within Livermore to accommodate expanding growth

- Awarded long-term contract to supply composite materials NASA’s Langley Research Center

- Achieves ISO 9001:2008 certification

- Becomes largest nationwide producer of Pickleball Paddle blanks

- Adds several Large Walk-in Oven to facility

- Expands machining capabilities with a 5 Axis CNC Machining Center

- Introduces ROMER Absolute Arm™ into Quality Center

- Starts manufacturing composite structures for a Silicon Valley-based telecommunication company

- Starts manufacturing rocket body fairings and assemblies

- Installs largest of 3 Autoclaves - 25ft ASC Autoclave

- Opens second location dedicated to retail distribution

- Installs new Joss Press, doubling flat panel output

- Moves retail facility to location three x size

- Launches new website

- Acquires new Joss Press and large capacity autoclave